The difference between thick-sheet thermoforming and injection molding processes

Category:

Author:

Origin:

Xinhua News Agency

Time of issue:

2023-11-17 22:00

Visits:

Difference between thick sheet thermoforming and injection molding

I. Overview

In the field of plastic product processing, thick sheet thermoforming and injection molding are common processing techniques. Although both use plastic materials for product processing, their principles, processes, and applicable scopes are quite different. The following will provide a detailed introduction from these aspects.

II. Principle

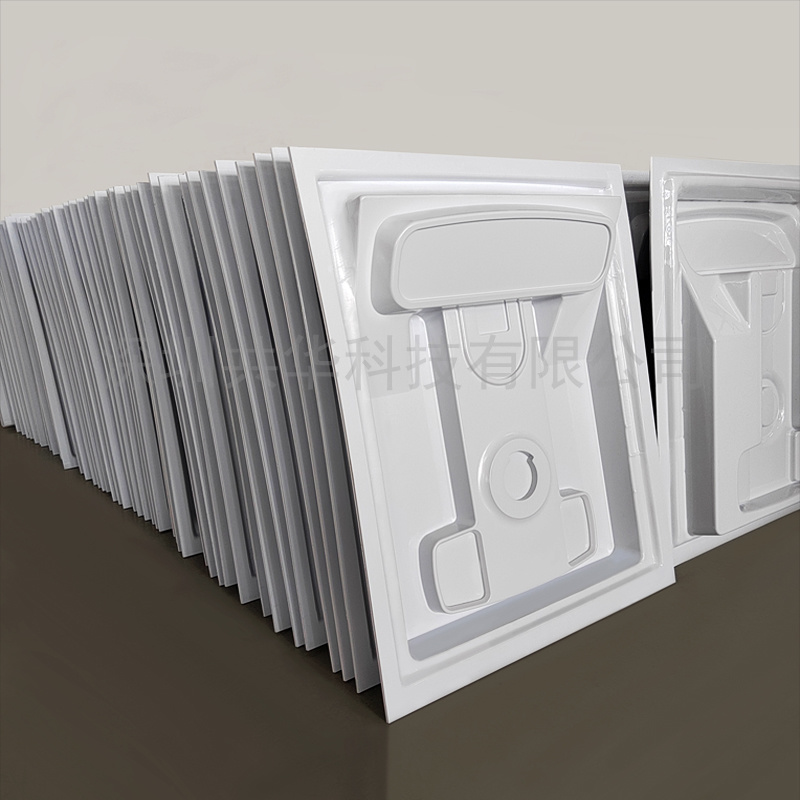

The principle of thick sheet thermoforming is to use plastic sheets, in a heated softened state, to form by negative pressure adsorption on the mold surface. The entire processing process requires first placing the plastic sheet in the heater of the thermoforming machine for preheating and softening, then using adsorption technology to adsorb the softened plastic sheet to the mold, and forming it on the mold. The principle of injection molding, however, is to inject heated and molten plastic granules into the mold under high pressure, allowing the plastic material to enter the mold, and then the plastic material cools in the mold to form the required plastic product.

III. Process

The process of thick sheet thermoforming is simpler than that of injection molding because it does not require special equipment such as injectors; only a thermoforming machine, mold, and preheating machine are needed. First, the plastic sheet is placed in the preheating machine for preheating, then placed on the thermoforming machine, and the softened plastic sheet is adsorbed to the mold surface through adsorption technology. After the plastic cools, it can be demolded. The entire process is simple and easy to operate, especially suitable for small-batch and multi-variety production.

The process of injection molding is more complex and requires special equipment such as injectors, molds, heaters, and coolers. The process is to first melt the plastic granules in the heater of the injection machine, then inject the plastic material into the mold through the injector, and after the plastic cools and forms in the mold, it is demolded. The entire process is more complex but can meet the needs of mass production.

IV. Applicable Scope

Thick sheet thermoforming is suitable for processing plastic products with larger material thickness and simpler shapes, such as oven trays and food packaging boxes. Because its process is relatively simple and the production cost is relatively low, it is suitable for small-batch and multi-variety production.

Injection molding, however, is suitable for producing products with complex shapes, precise dimensions, high quality requirements, and large batches, such as handles and machine housings. However, due to its higher requirements for equipment cost and energy consumption, its production cost is relatively high.

V. Summary

In general, thick sheet thermoforming and injection molding are common plastic product processing technologies, each with its own applicable occasions. Thick sheet thermoforming is suitable for small-batch, multi-variety production, while injection molding is suitable for large-batch, high-precision production. It is hoped that through this introduction, readers can better understand these two processing technologies and better choose the processing technology that suits their needs.